![]() |

|

|

|

|

|

|

|

|

TC-2060 can be widely used in various materials, such as paper,film, rubber, fiber, metal foil, etc., and it is suitable for unwinding/rewinding in various process conditions for automatic tension control.

Multi-functions of operation panel with multi-functions of terminal input can match production conditions for various mechanic equipment, having two-chips of CPU design, the capability of high-speed operation, and perfect control software, which shows the performance of accurate operation

and stability. |

|

|

• |

The functions of unwinding / infeed, center proportional linkage, and rewinding / receiving can be set by the internal DIP switch of TC-2060. |

• |

It includes the digital type of line-speed proportional linkage function, which can make material stable tension in the process of production. |

• |

Multi-level P.I.D computing capability can fast stabilize material tension variations in the process of production, meanwhile,having reverse P.I.D. Computing Function and can cooperate with the servo controller for active feeding. |

| • |

Accepting tension detection signal (LMS series, PDSA series of tension detectors) as the tension signal source for computing material tension in the production process. |

| • |

Large subtitles high brightness LED numeric display, which can monitor remotely, switch-key can change the display unit kg.N.%... in operation. |

| • |

There are four rows of LCDs that can monitor four data records simultaneously. |

| • |

Two sets of terminals accepted external analog input signals that can be set for automatic tension control, manual tension control, and taping tension control. |

| • |

Two sets of terminals accepted external digital input signals that can be set for the roller switch or the auxiliary functions in the start/stop. |

| • |

There are various taping-tension curves can be selected. |

| • |

It includes an output of DC 0 ~ 10V to directly control the magnetic powder brake. |

| • |

It can simultaneously output two sets of control signals for the drive speed and current command. |

| • |

It includes RS-485 communication function, and could connect to PLC, human machine interface, and industrial computer for control. |

| • |

The terminal’s output signal of DC 0 ~ 10V could directly control the torque controller, a current-control type of Vector Inverter,DC motor drive, and servo motor drive. |

| • |

Working with LMS series of load cell, rated load of 5Kg ~ 1,000Kg (50NM~10,000NM). |

|

|

|

|

|

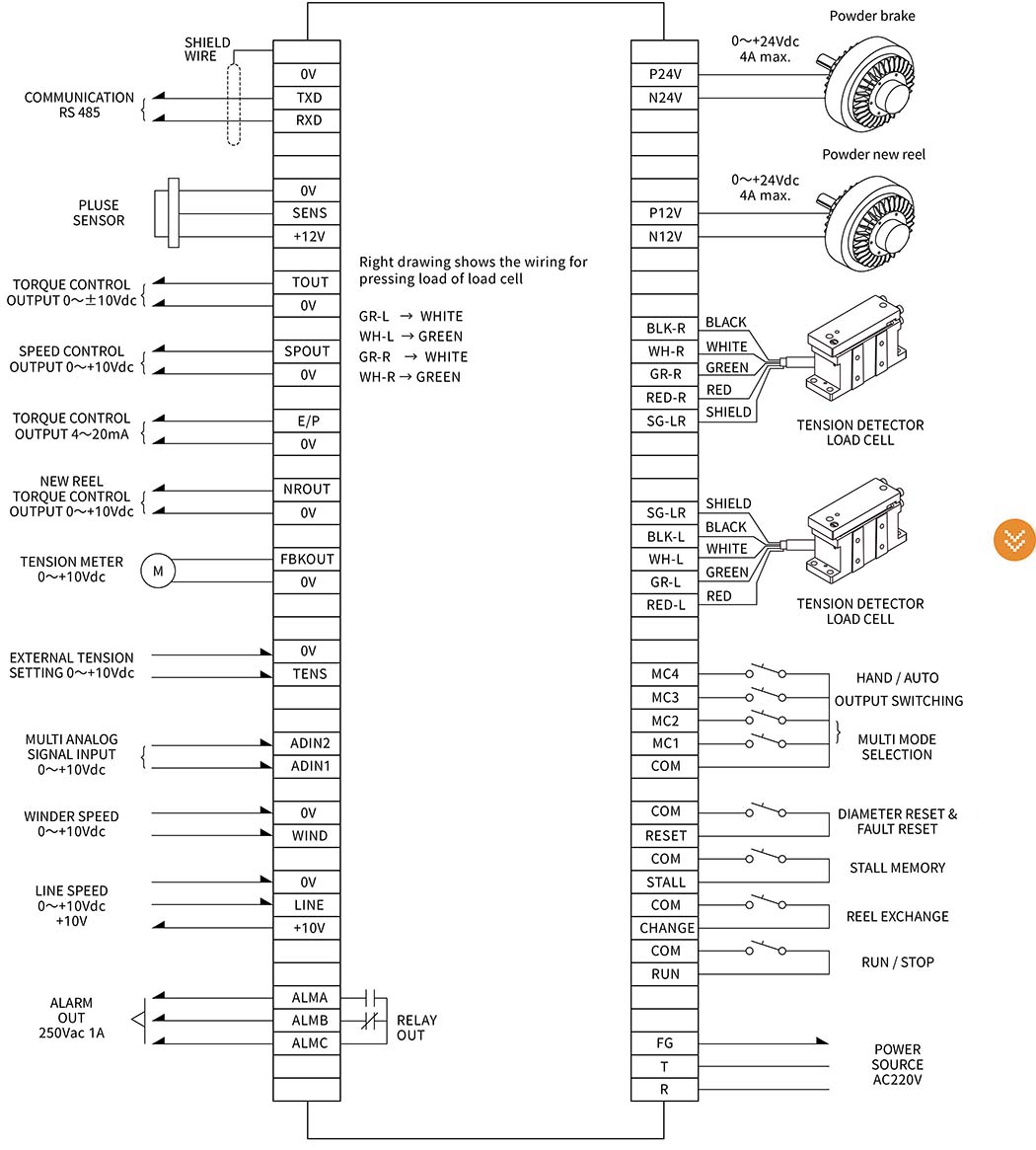

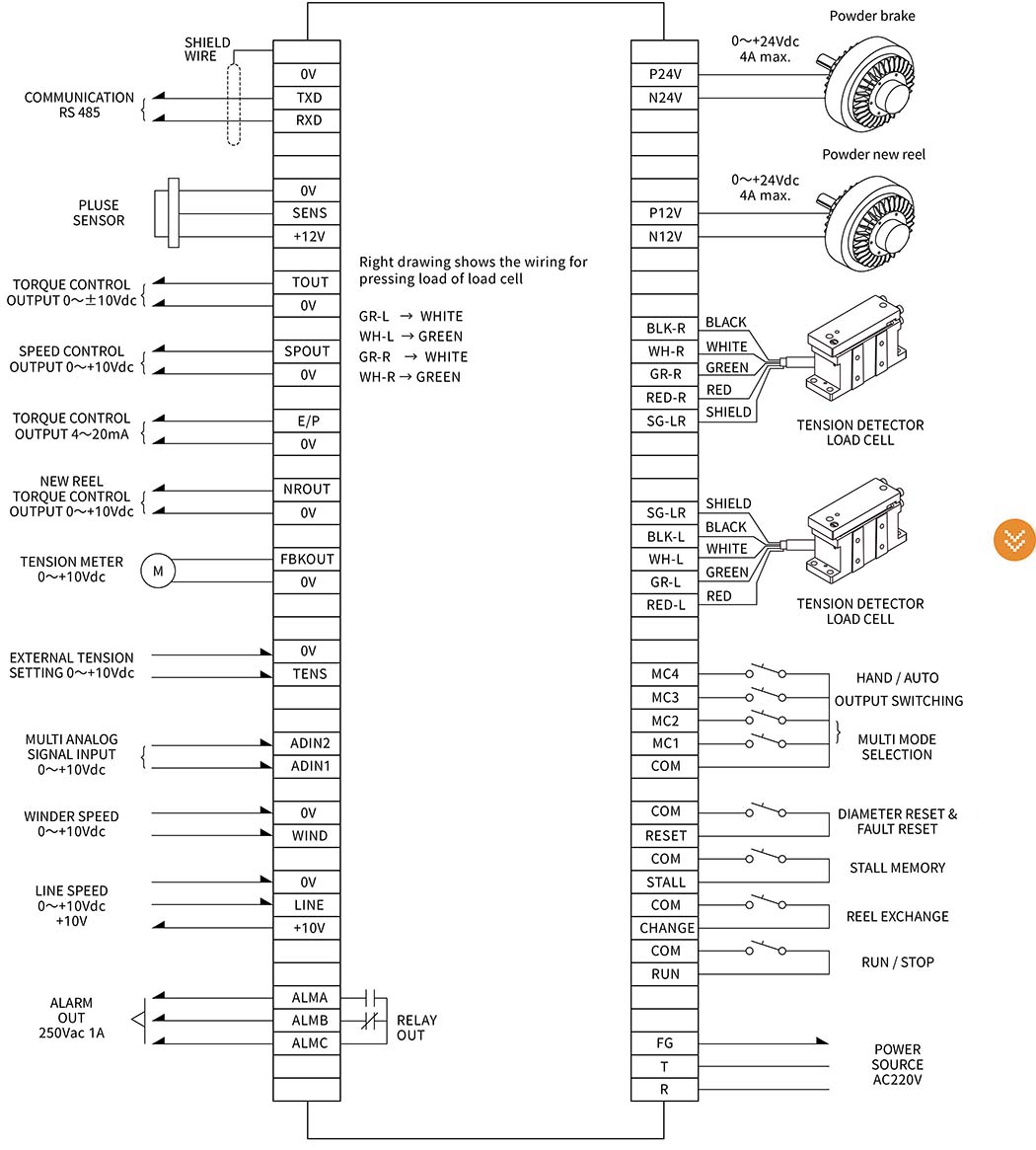

| Tension controller TC-2060 Wiring diagram |

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() |

| |

|

| Euntay Electric Co., Ltd. |

Motion Control System Manufacturer in Taiwan, |

| Tension Control System Manufacturer in Taiwan, |

| Edge Position Control System Manufacturer in Taiwan, |

| Tension Controller, Load Cell , Tension Detector, Sensor |

| Edge Position Controller, EPC, Edge Guide Sensor,Web Guiding, |

Ultrasonic EPC Detector , Infrared EPC Detector , Electric Cylinder , |

| Hydraulic type Drive, Double loop Hydraulic Drive, Web Guide |

| Web Guiding Machine, DC Motor Drive, Digital DC Motor Drive |

|

|

|

|