|

|

|

|

|

|

|

| Drive Device EPM-52 uses DC Servo Motor and combines edge-position detector, controller EPD-335 or EPD-58LR and drive mechanism to achieve the purpose of moving material’s edge-position. |

|

|

• |

High output-torque and fast response, could match the requirement of continuous operation of Stenter machine. |

• |

The mechanic features of accurate-control of servo motor, which is suitable for frequently low-speed condition of clockwise and anti-clockwise operation and could track, positing stably and smoothly. |

• |

Equipping with high-efficiency gear, therefore, the reducer has high durability. |

|

|

|

|

|

| Edge Position Drive Device EPM-52 Specifications |

|

|

| System |

|

| Rated armature voltage |

DC75V |

| Rated armature current |

3.0A |

| Rated output power |

220W |

| Rated output torque |

2,000N |

| Rated rotation speed |

3,000 r.p.m |

| Tracking speed |

0 ~ 120mm/S |

| Insulation class |

H |

| Ambient temperature |

0°C ~40°C |

| Ambient humidity |

85% RH below (No condensation) |

| Environment requirement |

Without corroded gas, flammable gas and conduction dust,

below 1000 meters above sea level |

| Weight |

23Kg |

| Applicable controller |

EPD58LR (DSD-65A) |

|

|

|

| Mechanic data |

|

| Mounting |

Screwed-mount |

| Housing |

Iron-shell |

| Dimension |

Refer to “Dimension Diagram” |

|

|

|

|

|

|

|

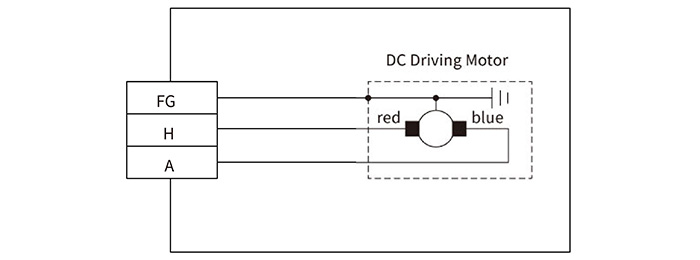

| Edge Position Drive Device EPM-52 Wiring Diagram |

|

|

|

|

|

|

|

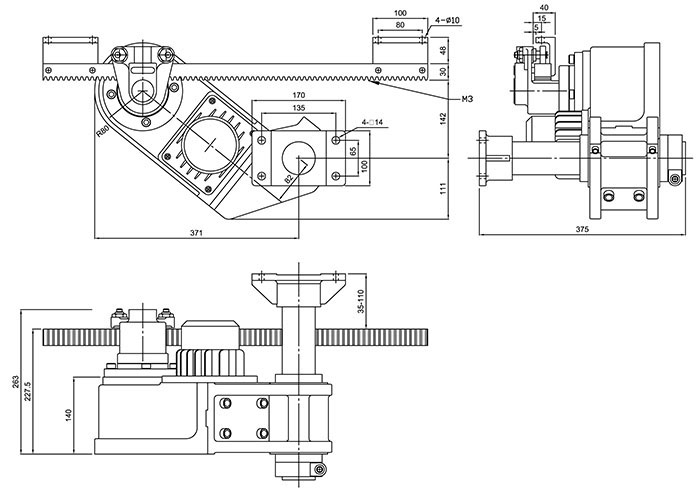

| Edge Position Drive Device EPM-52 Dimension Diagram |

|

|

|

|

|

|

| |

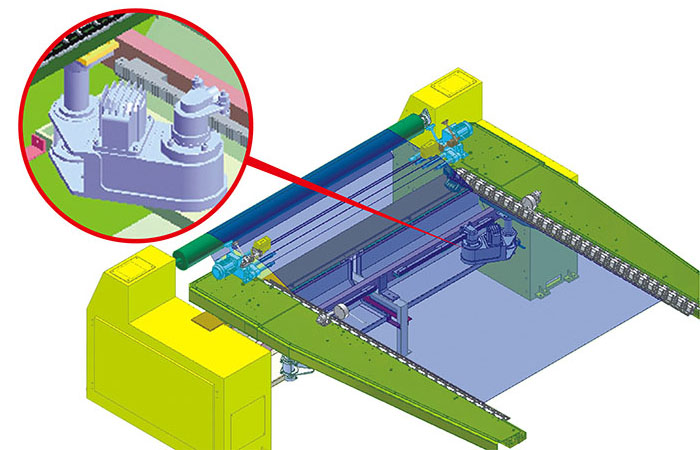

| Edge Position Drive Device EPM-52 Application Diagram |

| |

|

| |

| Drive device EPM-52 is applied to the fabric edge-position control in Stenter machine. |

|

|

|

|

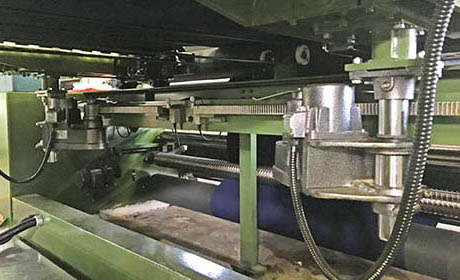

| Edge Position Drive Device EPM-52 Application Examples |

|

|

|

|

|

| Drive device EPM-52 is applied to the fabric edge-position control in Stenter machine. |

|

|

|

|

|

|

|

| Generous Purpose EPC System |

|

|

|

|

|

|

|

|

|

|